Client: Hastings District Council

Specifier: Tonkin + Taylor

Originally established in the 1940s, Lowes Pit began as a gravel and rock quarry used to support local road construction in Hastings. Over time, the pit filled with water and transitioned into a stormwater catchment for the surrounding industrial zone. With the area’s growth, traditional piped stormwater infrastructure proved inadequate due to shallow pipe inverts, resulting in untreated stormwater being directed into the pit.

This runoff was found to be heavily contaminated with a range of pollutants, including lead, zinc, copper, hydrocarbons, and E. coli — raising concerns about environmental health and downstream impacts, particularly the potential risk to nearby groundwater sources.

Retrofitting an effective stormwater treatment solution into an established and shallow system posed a major design and engineering challenge. The system had to address significant contaminant loads while fitting within tight vertical constraints.

The Solution

To meet these requirements, the Hastings District Council selected a multi-layered treatment approach using:

- Filterra® Bioscape® – A high-performance biofiltration system offering the highest metal removal efficiency among available treatment technologies, ideal for the Council's targeted environmental outcomes.

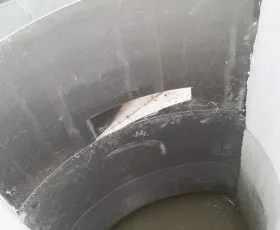

- LittaTrap™ Catchpit Inserts – Installed throughout the catchment, these provided essential pre-treatment by capturing gross pollutants, trash, and debris before runoff entered the treatment train.

A pumped first flush system was designed to divert the most contaminated portion of stormwater to trade waste facilities, significantly reducing pollutant loads before they entered the Filterra® Bioscape® system. Once this initial flush is removed, typical stormwater is effectively treated through the biofiltration process.